DHR4E4C101K2BB Ver la hoja de datos (PDF) - Unspecified

Número de pieza

componentes Descripción

Lista de partido

DHR4E4C101K2BB Datasheet PDF : 20 Pages

| |||

!Note •PPleleaasseerreeaaddrraatitninggaanndd!!CCAAUUTTIOIONN((foforrsstotorraaggee,,ooppeerraatitningg,,rraatitningg,,ssooldldeerriningg,,mmoouunntitninggaannddhhaannddlilningg))ininththisisPcDatFalcoagtatolopgrteovepnretvsemnot ksimngokaindg/oarndb/uorrnbinugr,neintgc., etc.

C41E2.pdf 03.4.16

•TThhisisccaatatalologghhaassoonnlylytytyppiciacal sl pspeecicficfiactaiotinosn.sTbheecraeufosree,thyeorueaisrenroeqsupeascteedfotrodaeptapirloevdesopuercpifircoadtuiocntss.pTehceifirceafotioren,spoleratosetranpsparocvt ethoeuarppprroodvuacltsshpeeectifoicraptiroondsucotrstrpaencsifaiccatitohnesabpepfororevaolrsdheerientgf.or product specifications before ordering.

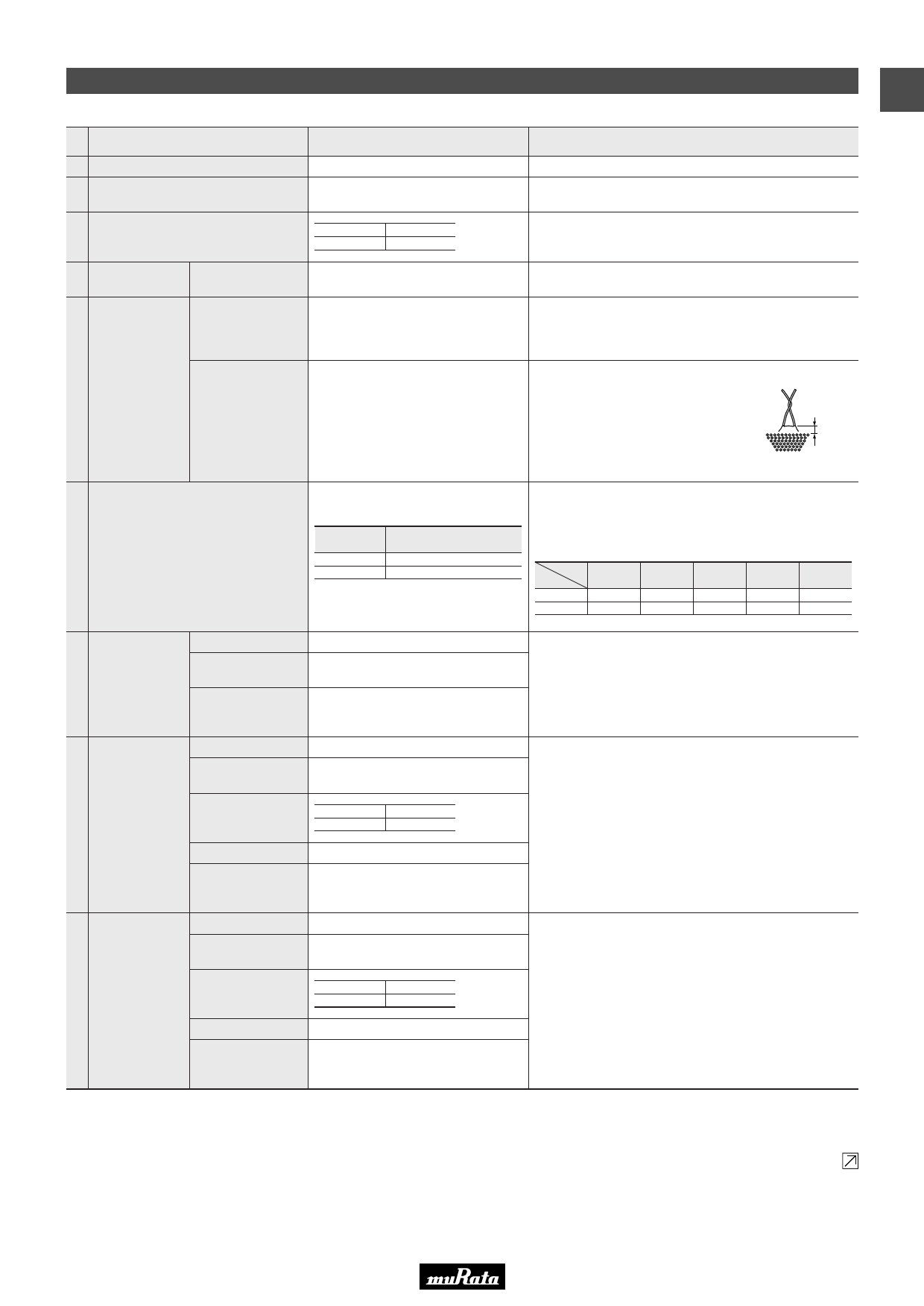

Specifications and Test Methods 1

No.

Item

1 Operating Temperature Range

2 Capacitance

3 Dissipation Factor (D.F.)

4

Insulation

Resistance (I.R.)

Between

Lead Wires

Between

Lead Wires

5

Dielectric

Strength

Body Insulation

6 Temperature Characteristics

Specifications

-25 to +100˚C

Within the specified tolerance.

ZM

1.0% max.

B

2.5% max.

10000MΩ min.

No failure.

No failure.

Temp. Char.

ZM

B

Temp. Coefficient or

Max. Cap. Change

-4700±1000ppm/˚C

±10%

Testing Method

—

The capacitance should be measured at 20°C with 1±0.2kHz

and AC 5V(r.m.s.) max.

Same condition as capacitance.

The insulation resistance should be measured with DC1000V

within 60±5 sec. of charging.

The capacitor should not be damaged when DC voltage of

150% of the rated voltage is applied between the lead wires for

60±5 sec. in insulating liquid or gas.

(Charge/Discharge currentV50mA)

The capacitor is placed in the container with

metal balls of diameter 1mm so that each

lead wire, shortcircuited, is kept

approximately 2mm off the metal balls as

shown in the figure at right, and DC voltage

of 3kV is applied for 10 sec. between

capacitor lead wires and metal balls.

(Charge/Discharge currentV50mA)

Approx. 2mm

Metal balls

The capacitance measurement should be made at each step

specified in table.

Capacitance change from the value of step 3 should not

exceed the limit specified.

Step

Char.

ZM

B

1

—

20±2˚C

2

—

-25±3˚C

3

20±2˚C

20±2˚C

4

85±2˚C

85±2˚C

5

20±2˚C

20±2˚C

Appearance

Capacitance

7 Soldering Effect Change

Dielectric Strength

(Between

Lead Wires)

Appearance

Capacitance

Change

Humidity

8

(Under

Steady

D.F.

State)

I.R.

Dielectric Strength

(Between

Lead Wires)

Appearance

Capacitance

Change

No marked defect.

Within ±10%

No failure.

No marked defect.

Within ±10%

ZM

1.5% max.

B

4.0% max.

5000MΩ min.

No failure.

No marked defect.

Within ±10%

9 Life

D.F.

ZM

1.5% max.

B

4.0% max.

The lead wires should be immersed into the melted solder of

350±10˚C up to about 1.5 to 2.0mm from the main body for

3.5±0.5 sec.

Post-treatment: Capacitor should be stored for 24±2 hrs. at

*room condition.

Set the capacitor for 240±8 hrs. at 40±2˚C in 90 to 95% relative

humidity.

Post-treatment: Capacitor should be stored for 1 to 2 hrs. at

*room condition.

Apply a DC voltage of 125% of the rated voltage for 1000+-048

hrs. in silicon oil at 85±2˚C.

Post-treatment: Capacitor should be stored for 24±2 hrs. at

*room condition.

(Charge/Discharge currentV50mA)

I.R.

5000MΩ min.

Dielectric Strength

(Between

Lead Wires)

No failure

(Note) Tests for Dielectric Strength (between lead wires), Charge Discharge Test, Humidity, Temperature Cycle and Life should be performed with

specimens having molded resin (MR1023C : made by Murata) extending over 3mm on all the surface.

* "room condition" Temperature: 15 to 35D, Relative humidity: 45 to 75%, Atmospheric pressure: 86 to 106kPa

Continued on the following page.

5