DHRB34C471M2BB Ver la hoja de datos (PDF) - Unspecified

Número de pieza

componentes Descripción

Lista de partido

DHRB34C471M2BB Datasheet PDF : 20 Pages

| |||

!Note •PPleleaasseerreeaaddrraatitninggaanndd!!CCAAUUTTIOIONN((foforrsstotorraaggee,,ooppeerraatitningg,,rraatitningg,,ssooldldeerriningg,,mmoouunntitninggaannddhhaannddlilningg))ininththisisPcDatFalcoagtatolopgrteovepnretvsemnot ksimngokaindg/oarndb/uorrnbinugr,neintgc., etc.

C41E2.pdf 03.4.16

•TThhisisccaatatalologghhaassoonnlylytytyppiciacal sl pspeecicficfiactaiotinosn.sTbheecraeufosree,thyeorueaisrenroeqsupeascteedfotrodaeptapirloevdesopuercpifircoadtuiocntss.pTehceifirceafotioren,spoleratosetranpsparocvt ethoeuarppprroodvuacltsshpeeectifoicraptiroondsucotrstrpaencsifaiccatitohnesabpepfororevaolrsdheerientgf.or product specifications before ordering.

1 Specifications and Test Methods

Continued from the preceding page.

No.

Item

Specifications

Testing Method

Appearance

Capacitance

Change

D.F.

I.R.

No marked defect.

Within ±10%

ZM

1.5% max.

B

4.0% max.

5000MΩ min.

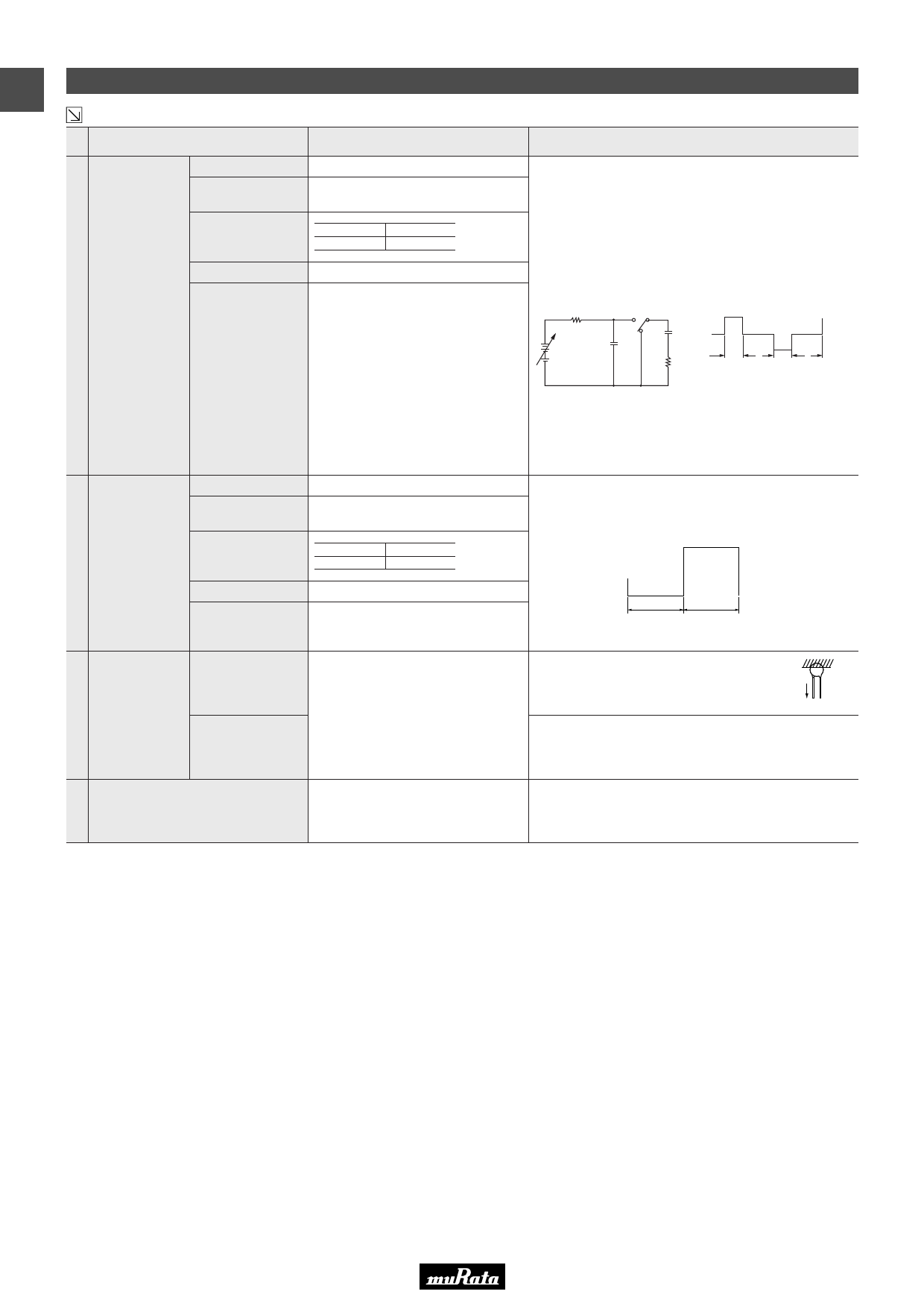

Charge discharge test should be measured in the following test

circuit and cycle.

Applied voltage : Rated voltage

Cycle time : 20000 cycle

Post-treatment : Capacitor should be stored for 4 hrs. at *room

condition.

Charge

10 Discharge

Test

Dielectric Strength

(Between

Lead Wires)

No failure.

Appearance

Capacitance

Change

No marked defect.

Within ±10%

<Circuit>

R1

SW

CX

C0

E

R2

<Cycle>

Charge Discharge

1

21

2

(sec.)

Cx : specimen

R1 : circuit protective resistor (300kΩ)

C0 : supplied energy for Cx. C0.=.10Cx

R2 : current limitting resistor (E/10Ω)

E : direct-current voltage source

Temperature cycle should be measured in the following test.

Cycle time : 5 cycle

Post-treatment : Capacitor should be stored for 4 hrs. at *room

condition.

11

Temperature

Cycle

D.F.

I.R.

Dielectric Strength

(Between

Lead Wires)

ZM

1.5% max.

B

4.0% max.

5000MΩ min.

No failure.

-30˚C

30

+100˚C

30

(min)

12

Strength

of Lead

Pull

Bending

Lead wire should not be cut off.

Capacitor should not be broken.

As shown in the figure at right, fix the body of the

capacitor and apply a tensile weight gradually to

each lead wire in the radial direction of the

W

capacitor up to 10N and keep it for 10±1 sec.

Each lead wire should be subjected to 5N of weight and bent

90˚ at the point of egress, in one direciton, then returned to its

original position and bent 90˚ in the opposite direction at the

rate of one bend in 2 to 3 sec.

13 Solderability of Leads

Lead wire should be soldered with

uniform coating on the axial direction

over 34– of the circumferential direction.

The lead wire of a capacitor should be dipped into a 25%

methanol solution of rosin and then into molten solder of

235±5˚C for 2±0.5 sec. In both cases the depth of dipping is up

to about 1.5 to 2.0mm from the root of lead wires.

(Note) Tests for Dielectric Strength (between lead wires), Charge Discharge Test, Humidity, Temperature Cycle and Life should be performed with

specimens having molded resin (MR1023C : made by Murata) extending over 3mm on all the surface.

* "room condition" Temperature: 15 to 35D, Relative humidity: 45 to 75%, Atmospheric pressure: 86 to 106kPa

6