LT1461-2.5 Ver la hoja de datos (PDF) - Linear Technology

Número de pieza

componentes Descripción

Lista de partido

LT1461-2.5

LT1461-2.5 Datasheet PDF : 12 Pages

| |||

LT1461-2.5

APPLICATIONS INFORMATION

or a region where the flexure of the board is minimum. The

package should always be mounted so that the leads

absorb the stress and not the package. The package is

generally aligned with the leads parallel to the long side of

the PC board as shown in Figure 5a.

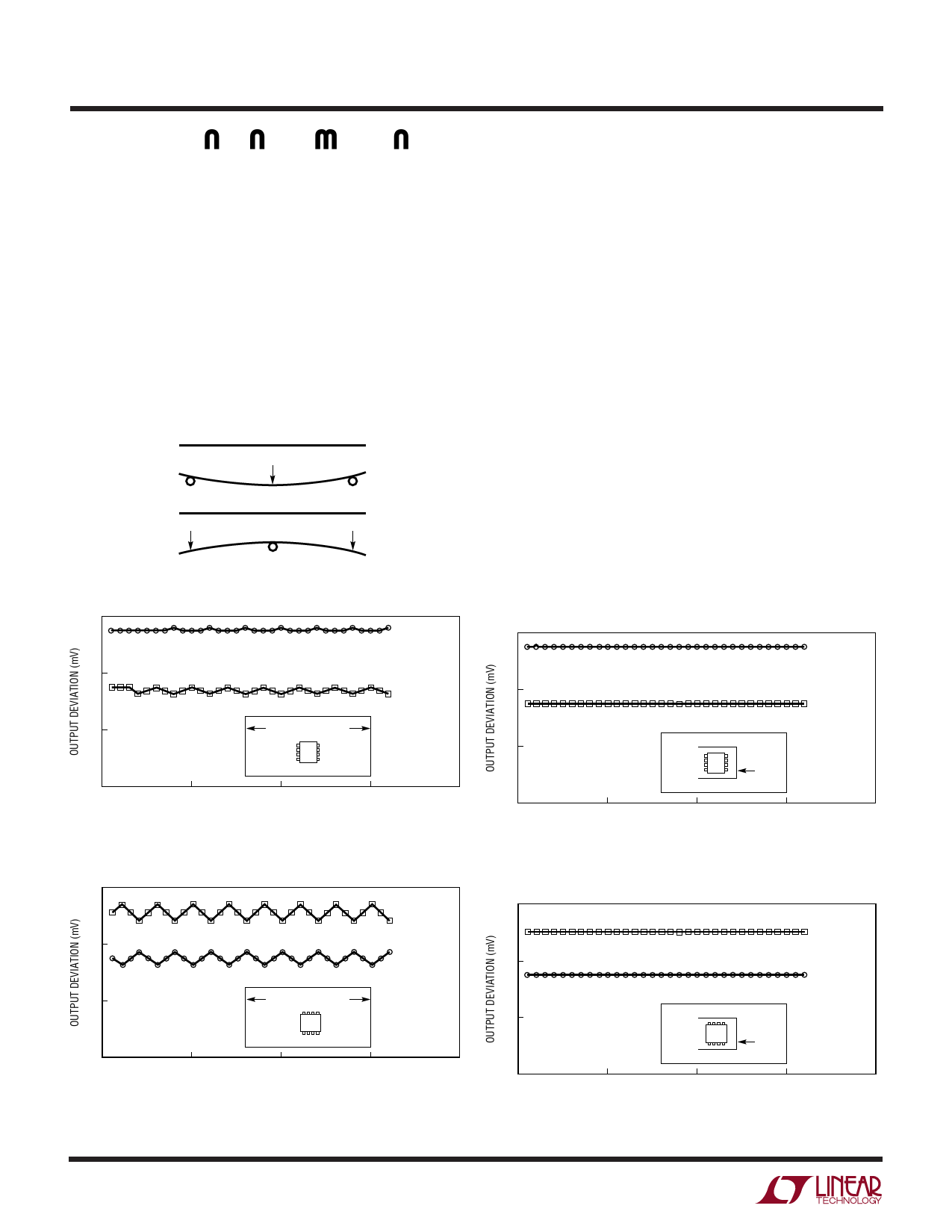

A qualitative technique to evaluate the effect of stress on

voltage references is to solder the part into a PC board and

deform the board a fixed amount as shown in Figure 4. The

flexure #1 represents no displacement, flexure #2 is

concave movement, flexure #3 is relaxation to no dis-

placement and finally, flexure #4 is a convex movement.

1

2

3

4

1461 F04

Figure 4. Flexure Numbers

2

This motion is repeated for a number of cycles and the

relative output deviation is noted. The result shown in

Figure 5a is for two LT1461S8-2.5s mounted vertically

and Figure 5b is for two LT1461S8-2.5s mounted horizon-

tally. The parts oriented in Figure 5a impart less stress into

the package because stress is absorbed in the leads.

Figures 5a and 5b show the deviation to be between 125µV

and 250µV and implies a 50ppm and 100ppm change

respectively. This corresponds to a 13- to 14-bit system

and is not a problem for most 10- to 12-bit systems unless

the system has a calibration. In this case, as with tempera-

ture hysteresis, this low level can be important and even

more careful techniques are required.

The most effective technique to improve PC board stress

is to cut slots in the board around the reference to serve as

a strain relief. These slots can be cut on three sides of the

reference and the leads can exit on the fourth side. This

“tongue” of PC board material can be oriented in the long

direction of the board to further reduce stress transferred

to the reference.

2

1

1

0

LONG DIMENSION

–1

0

10

20

30

FLEXURE NUMBER

Figure 5a. Two Typical LT1461S8-2.5s,

Vertical Orientation Without Slots

2

40

1461 F05a

0

SLOT

–1

0

10

20

30

40

FLEXURE NUMBER

1461 F06a

Figure 6a. Same Two LT1461S8-2.5s in Figure 5a, but with Slots

2

1

1

0

LONG DIMENSION

–1

0

10

20

30

FLEXURE NUMBER

Figure 5b. Two Typical LT1461S8-2.5s,

Horizontal Orientation Without Slots

40

1461 F05b

0

SLOT

–1

0

10

20

30

40

FLEXURE NUMBER

1461 F06b

Figure 6b. Same Two LT1461S8-2.5s in Figure 5b, but with Slots

8