AD2S1200 Ver la hoja de datos (PDF) - Analog Devices

Número de pieza

componentes Descripción

Lista de partido

AD2S1200 Datasheet PDF : 24 Pages

| |||

AD2S1200

Signal Degradation Detection

Degradation of signal (DOS) is detected when either resolver

input (Sin or Cos) exceeds the specified DOS Sin/Cos threshold

by comparing the monitor signal to a fixed maximum value.

DOS is also detected when the amplitude of the input signals

Sin and Cos mismatch by more than the specified DOS Sin/

Cos mismatch by continuously storing the minimum and

maximum magnitude of the monitor signal in internal registers,

and calculating the difference between the minimum and

maximum. DOS is indicated by a logic low on the DOS pin, and

is not latched when the input signals exceed the maximum

input level. When DOS is indicated due to mismatched signals,

the output is latched low until a rising edge of SAMPLE resets

the stored minimum and maximum values. The DOS condition

has priority over the LOT condition, as shown in Table 4. DOS

is indicated within 30° of angular output error worst case.

Loss of Position Tracking Detection

Loss of tracking (LOT) is detected for three separate conditions:

• When the internal error signal of the AD2S1200 has

exceeded 5°

• When the input signal exceeds the maximum tracking rate

of 60,000 rpm (1,000 rps)

• When the internal position (at the position integrator)

differs from the external position (at the position register)

by more than 5°

LOT is indicated by a logic low on the LOT pin, and is not

latched. LOT has a 4° hysteresis, and is not cleared until the

internal error signal or internal/external position mismatch is

less than 1°. When the maximum tracking rate is exceeded, LOT

is cleared when both the velocity is less than 1,000 rps and the

internal/external position mismatch is less than 1°. LOT can be

indicated for step changes in position (such as after a RESET

signal is applied to the AD2S1200), or for accelerations

>~85,000 rps2. LOT is useful as a built-in test (BIT) that the

tracking converter is functioning properly. The LOT condition

has lower priority than both the DOS and LOS conditions as

shown in Table 4. The LOT and DOS conditions cannot be

indicated at the same time.

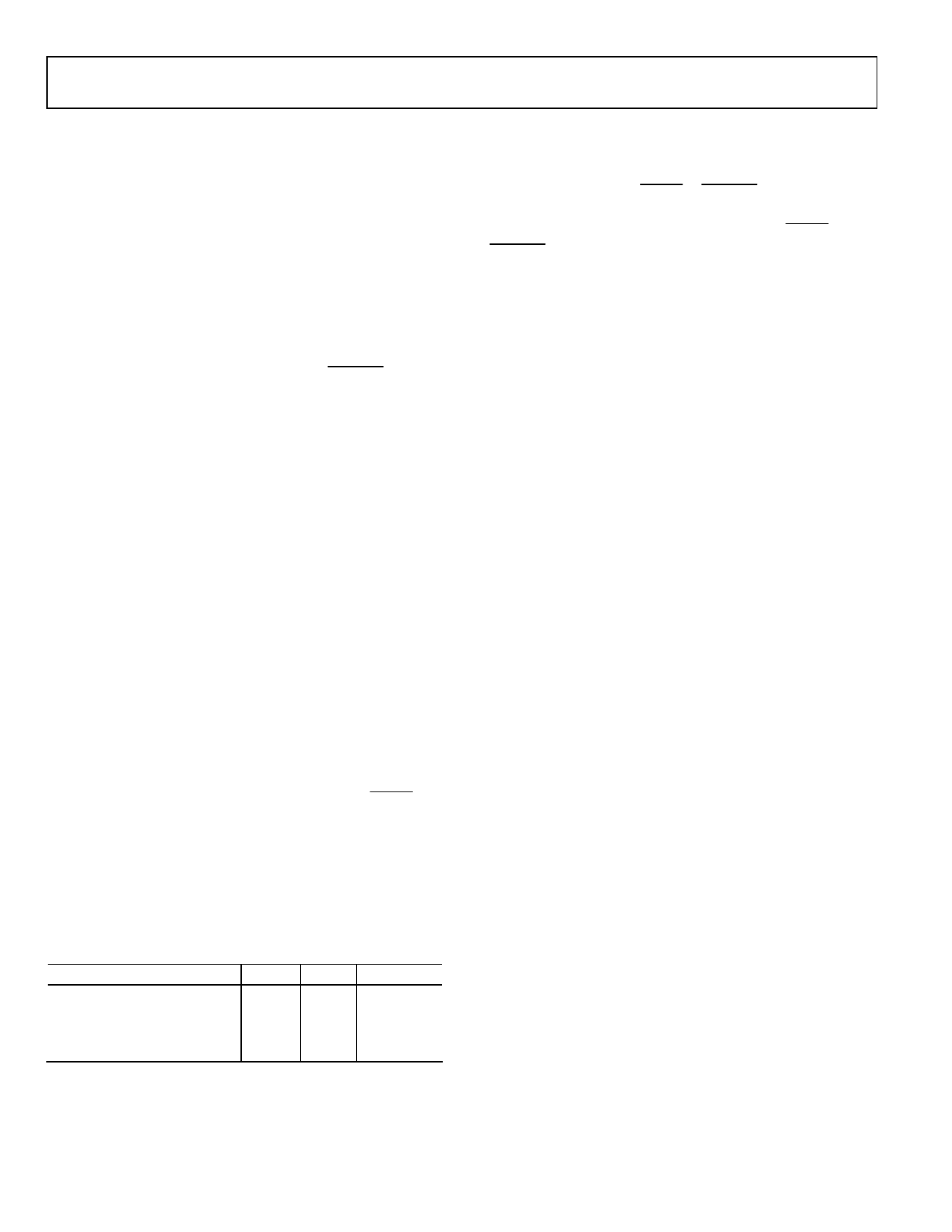

Table 4. Fault Detection Decoding

Condition

DOS LOT Priority

Loss of Signal

0

0

1

Degradation of Signal

0

1

2

Loss of Tracking

1

0

3

No Fault

1

1

Responding to a Fault Condition

If any fault condition (LOS, DOS, or LOT) is indicated by the

AD2S1200, the output data must be presumed to be invalid.

This means that even if a RESET or SAMPLE pulse releases the

fault condition, the output data may be corrupted, even though

a fault may not be immediately indicated after the RESET/

SAMPLE event. As discussed earlier, there are some fault

conditions with inherent latency. If the device fault is cleared,

there could be some latency in the resolver’s mechanical

position before the fault condition is re-indicated.

When a fault is indicated, all output pins will still provide data,

although the data may or may not be valid. The fault condition

will not force the parallel, serial, or encoder outputs to a known

state. However, a new startup sequence is recommended only

after a LOS fault has been indicated.

Response to specific fault conditions is a system-level

requirement. The fault outputs of the AD2S1200 indicate that

the device has sensed a potential problem with either the

internal or external signals of the AD2S1200. It is the

responsibility of the system designer to implement the

appropriate fault-handling schemes within the control hardware

and/or algorithm of a given application based on the indicated

fault(s) and the velocity or position data provided by the

AD2S1200.

False Null Condition

Resolver-to-digital converters that employ Type II tracking

loops based on the error equation (Equation 3) presented in the

Principle of Operation section can suffer from a condition

known as “false null.” This condition is caused by a metastable

solution to the error equation when θ − ϕ = 180°. The

AD2S1200 is not susceptible to this condition because its

hysteresis is implemented externally to the tracking loop.

Because of the loop architecture chosen for the AD2S1200, the

internal error signal always has some movement (1 LSB per

clock cycle), and so, in a metastable state, the converter will

always move to an unstable condition within one clock cycle,

causing the tracking loop to respond to the false null condition

as if it were a 180° step change in input position (the response

time is the same as specified in Dynamic Performance section

of Table 1). Therefore, it is impossible to enter the metastable

condition any time after the startup sequence as long as the

resolver signals are valid. However, in a case of a loss of signal, a

full reset is recommended to avoid the possibility of a false null

condition. The response to the false null condition has been

included in the value of tTRACK provided in the Supply

Sequencing and Reset section.

Rev. 0 | Page 10 of 24