HS-80C86RH(1995) Ver la hoja de datos (PDF) - Intersil

Número de pieza

componentes Descripción

Lista de partido

HS-80C86RH Datasheet PDF : 37 Pages

| |||

HS-80C86RH

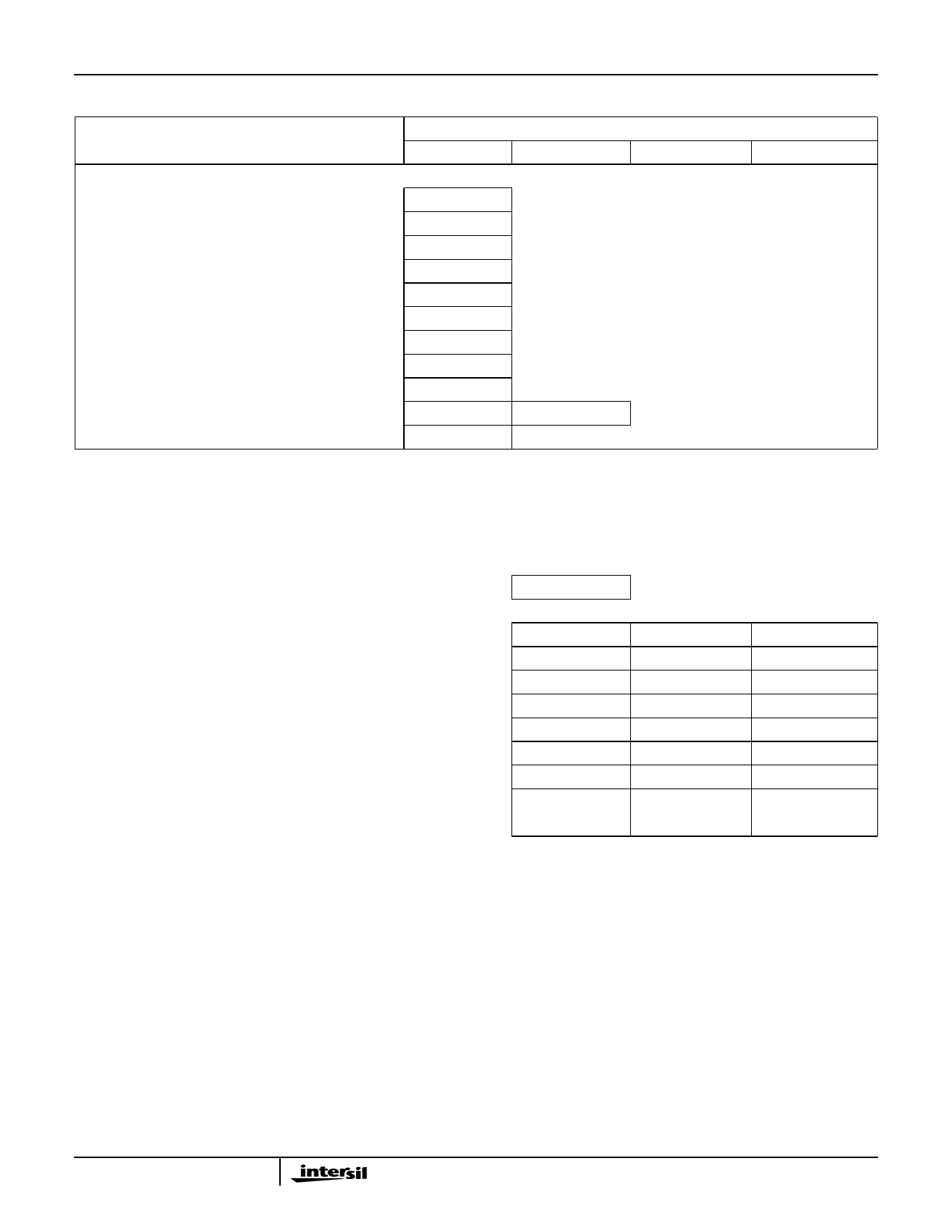

Intersil Space Level Product Flow - Q

All Lots - Wafer Lot Acceptance (Including SEM)

Method 5007

Each Wafer - GAMMA Radiation Verification,

Two samples/wafer, 0 rejects, Method 1019

100% Nondestructive Bond Pull, Method 2023

Sample - Wire Bond Pull Monitor, Method 2011

Sample - Die Shear Monitor, Method 2019 or 2027

100% Internal Visual Inspection, Method 2010, Condition A

100% Temperature Cycle - Method 1010, Condition C,

10 cycles

100% Constant Acceleration, Method 2001, Condition

Per Method 5004

100% Interim Electrical Test 1 (T1)

100% Delta Calculation (T0-T1)

100% PDA 1, Method 5004 (Note 1)

100% Dynamic Burn-In, Condition D, 240 hours, +125oC or

Equivalent Per Method 1015

100% Interim Electrical Test 2 (T2)

100% Delta Calculation (T0-T2)

100% PDA 2, Method 5004 (Note 2)

100% Final Electric Test (T3)

100% Fine/Gross Leak, Method 1014

100% Radiographic, Method 2012 (Note 3)

100% PIND - Method 2020, Condition A

100% External Visual, Method 2009

100% External Visual

Sample - Group A, Method 5005 (Note 4)

100% Serialization

Sample - Group B, Method 5005 (Note 5)

100% Initial Electrical Test (T0)

Sample - Group D, Method 5005 (Notes 5, 6)

100% Static Burn-In 1, Method 1015, Condition A or B,

72 Hours Minimum, 125oC minimum

NOTES:

100% Data Package Generation (Note 6)

1. Modified SEM Inspection, not compliant to MIL-STD-883, Method 2018. This device does not meet the Class S minimum metal step cov-

erage of 50%. The metal does meet the current density requirement of <2 E5 A/cm2. Data provided upon request.

2. Failures from subgroups 1, 7 and deltas are used for calculating PDA. The maximum allowable PDA = 5% with no more than 3% of the

failures from subgroup 7.

3. Radiographic (X-Ray) inspection may be performed at any point after serialization as allowed by Method 5004.

4. Alternate Group A testing may be performed as allowed by MIL-STD-883, Method 5005.

5. Group B and D inspections are optional and will not be performed unless required by the P.O. When required, the P.O. should include

separate line items for Group B test, Group B samples, Group D tests and Group D samples.

6. Group D Generic Data, as defined by MIL-I-38535, is optional and will not be supplied unless required by the P.O. When required, the

P.O. should include separate line items for Group D generic data. Generic Data is not guaranteed to be available and is therefore not

available in all cases.

7. Data Package Contents:

• Cover Sheet (Intersil Name and/or Logo, P.O. Number, Customer Part Number, Lot Date Code, Intersil Part Number, Lot Number, Quan-

tity). Wafer Lot Acceptance Report (Method 5007) to include reproductions of SEM photos with percent of step coverage.

• GAMMA Radiation Report. Contains Cover page, disposition, Rad Dose, Lot Number, test package used, specification numbers, test

equipment, etc. Radiation Read and Record data on file at Intersil.

• X-Ray Report and Film, including penetrameter measurements.

• Lot Serial Number Sheet (Good Unit(s) Serial Number and Lot Number).

• Variables Data (All Delta operations). Data is identified by serial number. Data header includes lot number and date of test.

• Group B and D attributes and/or Generic data is included when required by P.O.

• The Certificate of Conformance is a part of the shipping invoice and is not part of Data Book. The Certificate of Conformance

is signed by an authorized Quality Representative.

Spec Number 518055

883