ADM1023 Ver la hoja de datos (PDF) - Analog Devices

Número de pieza

componentes Descripción

Lista de partido

ADM1023 Datasheet PDF : 12 Pages

| |||

ADM1023

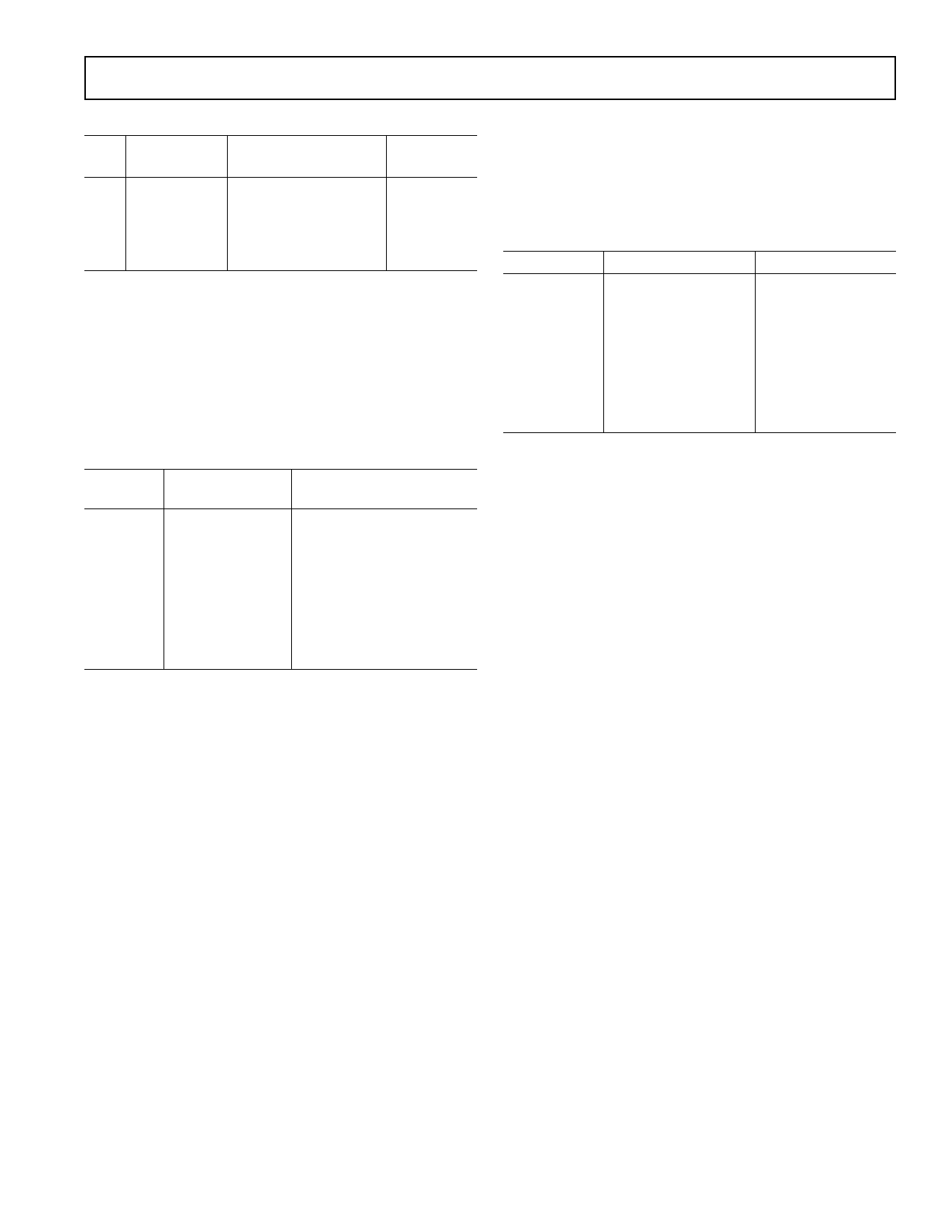

Table VI. Configuration Register Bit Assignments

Bit Name

Function

7

MASK1

0 = ALERT Enabled

1 = ALERT Masked

6

RUN/STOP 0 = Run

1 = Standby

5–0

Reserved

Power-On

Default

0

0

0

Conversion Rate Register

The lowest three bits of this register are used to program the

conversion rate by dividing the ADC clock by 1, 2, 4, 8, 16, 32,

64, or 128, to give conversion times from 125 ms (Code 07h) to

16 seconds (Code 00h). This register can be written to and read

back over the SMBus. The higher five bits of this register are

unused and must be set to zero. Use of slower conversion times

greatly reduces the device power consumption, as shown in

Table VII.

Table VII. Conversion Rate Register Codes

Data

00h

01h

02h

03h

04h

05h

06h

07h

08h to FFh

Conversion/sec

0.0625

0.125

0.25

0.5

1

2

4

8

Reserved

Average Supply Current

A Typ at VCC = 3.3 V

150

150

150

150

150

150

160

180

Limit Registers

The ADM1023 has six limit registers to store local and remote,

high and low temperature limits. These registers can be written

to and read back, over the SMBus. The high limit registers per-

form a > comparison while the low limit registers perform a

< comparison. For example, if the high limit register is programmed

as a limit of 80°C, measuring 81°C will result in an alarm condi-

tion. Even though the temperature range is 0 to 127°C, it is

possible to program the Limit Register with negative values.

This is for backwards-compatibility with the ADM1021.

One-Shot Register

The one-shot register is used to initiate a single conversion and

comparison cycle when the ADM1023 is in standby mode, after

which the device returns to standby. This is not a data register as

such and it is the write operation that causes the one-shot conver-

sion. The data written to this address is irrelevant and is not stored.

SERIAL BUS INTERFACE

Control of the ADM1023 is carried out via the serial bus. The

ADM1023 is connected to this bus as a slave device, under the

control of a master device.

ADDRESS PINS

In general, every SMBus device has a 7-bit device address (except

for some devices that have extended, 10-bit addresses). When

the master device sends a device address over the bus, the slave

device with that address will respond. The ADM1023 has two

address pins, ADD0 and ADD1, to allow selection of the device

address, so that several ADM1023s can be used on the same bus,

and/or to avoid conflict with other devices. Although only two

address pins are provided, these are three-state, and can be

grounded, left unconnected, or tied to VDD, so that a total of

nine different addresses are possible, as shown in Table VIII.

It should be noted that the state of the address pins is only sampled

at power-up, so changing them after power-up will have no effect.

Table VIII. Device Addresses

ADD0

ADD1

Device Address

0

0

0011 000

0

NC

0011 001

0

1

0011 010

NC

0

0101 001

NC

NC

0101 010

NC

1

0101 011

1

0

1001 100

1

NC

1001 101

1

1

1001 110

ADD0, ADD1 sampled at power-up only.

The serial bus protocol operates as follows:

1. The master initiates data transfer by establishing a START condi-

tion, defined as a high-to-low transition on the serial data line

SDATA, while the serial clock line SCLK remains high. This

indicates that an address/data stream will follow. All slave

peripherals connected to the serial bus respond to the START

condition and shift in the next eight bits, consisting of a 7-bit

address (MSB first) plus an R/W bit, which determines the

direction of the data transfer, i.e., whether data will be written

to or read from the slave device.

The peripheral whose address corresponds to the transmitted

address responds by pulling the data line low during the low

period before the ninth clock pulse, known as the Acknowledge

Bit. All other devices on the bus now remain idle while the

selected device waits for data to be read from or written to it.

If the R/W bit is a 0, the master will write to the slave device. If

the R/W bit is a 1, the master will read from the slave device.

2. Data is sent over the serial bus in sequences of nine clock

pulses, eight bits of data followed by an acknowledge bit

from the slave device. Transitions on the data line must occur

during the low period of the clock signal and remain stable

during the high period, as a low-to-high transition when the

clock is high may be interpreted as a STOP signal. The number

of data bytes that can be transmitted over the serial bus in a

single READ or WRITE operation is limited only by what the

master and slave devices can handle.

3. When all data bytes have been read or written, stop condi-

tions are established. In WRITE mode, the master will pull

the data line high during the 10th clock pulse to assert a STOP

condition. In READ mode, the master device will override

the acknowledge bit by pulling the data line high during the

low period before the ninth clock pulse. This is known as No

Acknowledge. The master will then take the data line low

during the low period before the 10th clock pulse, then high

during the 10th clock pulse to assert a STOP condition.

Any number of bytes of data may be transferred over the serial

bus in one operation, but it is not possible to mix read and write

in one operation, because the type of operation is determined

at the beginning and cannot subsequently be changed without

starting a new operation.

REV. A

–9–